CELAB x CTP publish study on recyclability of silicone release liners

- July 3, 2024

- Press Release

CELAB x CENTRE TECHNIQUE DU PAPIER STUDY: Glassine and CCK Release Liners Proven Recyclable

EXECUTIVE SUMMARY – A study to assess the recyclability of silicone release liners for CELAB was carried out by the CTP (Centre Technique du Papier, France) looking at the two most commonly used types of silicone release liners for self-adhesive labels: glassine and CCK. The CTP study considered the recyclability of both release liners as pure streams following CEN standard (EN 13430), which concluded that they are both recyclable according to EU guidelines. A further part of the CTP study looked at the behaviour of both release liner grades in a pilot-scale ‘mixed’ recycling process and concluded that there was no detrimental effect of these release liner grades on the recycling of mixed paper. It should be noted that in some ‘real-world’ recycling operations (particularly continuous pulping processes), the residence time in the continuous pulper may be prolonged to reach a sufficient level of disintegration for the liners.

INTRODUCTION: CELAB EUROPE is a collaboration of the whole self-adhesive label value chain to promote and enable the recycling of both release liners and matrix materials in order to build a sustainable self-adhesive labelling industry with a more circular approach to business. As part of the efforts promoting release liner recycling, CELAB EUROPE has sponsored research with globally recognised expert institutes to assess the behaviour of release liners when are handled by industrial recycling processes. As part of these efforts, in early 2024 CELAB-Europe sponsored research at the Centre Technique du Papier (CTP), in Grenoble, France to understand the behaviour of paper-based release liners in typical paper recycling processes in order to assess their suitability for industrial paper recycling operations.

EXPERIMENTAL SETUP DETAILS: For the recycling evaluations by CTP two different types of paper-based release liner were selected on the basis that they would represent the most commonly used types of release liner for self-adhesive labelling;

- One side silicone coated 60g Glassine.

- One side silicone coated 125g Clay Coated Kraft (CCK)

Both substrates were from standard industrial scale production processes where the release liners were coated with ‘typical’ levels of silicone release coating and were delivered in reel format (as might be typically expected as waste stream from a labelling applicator). The assessment of the recyclability of the release liners was then evaluated in two separate stages. Firstly a ‘lab-scale’ recyclability assessment following different standards (ISO 5263-1 standard for pulping and Tappi-Ansi T275sp18 for screening), and then secondly a ‘pilot-scale’ processability assessment using a mixed paper source in order to assess the ease of removal of coloured coating in a mixed paper recycling process.

RECYCLABILITY ASSESSMENT (LAB-SCALE) – Assessment of the recyclability of the two different types of release liner was carried out in accordance with ISO 5263-1 Disintegration of Chemical Pulps. This standard was chosen based on the type of base papers that were used as release base in this case. This describes the laboratory-scale pulping conditions which are required and tests which are carried out during the pulping process and on the final pulps and residues produced. The standard “neutral” conditions were used, with one slight modification to the temperature (in order to simulate the typical recycled process water temperature in industrial repulping operations).

| PULPING DURATION | 15 MINUTES |

| CONSISTENCY | 3% |

| PULPING TEMPERATURE | 40°C |

| CHEMICAL ADDITIVES | NONE ADDED |

After 15 min of pulping the pulps would then be visually assessed (to confirm good separation of fibres and any discoloration of the water due to bleeding of inks/dyes), and then through a 20min screening process to assess the efficiency of fibre separation followed by a heavyweight cleaning step if needed (to remove unwanted suspended materials such as glues, plastic particles and metals). The final screened pulp was then used to make handsheets (in accordance with ISO 5269-2) to assess visual paper quality and possible tackiness effect or not.

The results showed that both Glassine and CCK release liners could easily be disintegrated after 15min of pulping with only a few coating particles in suspension an NO discoloration of the water. For the screening step the Glassine release liner showed very low levels of rejects (1.3% in total (coarse and fine screening steps)), whilst the CCK showed a significant level at the Coarse screening step and low levels at the fine screening step (overall 7.1% from both screening steps). Both pulp suspensions were clean enough not to need a heavyweight cleaning stage. Handsheets passed the requirements with the only comment that in both cases there are still some ‘particles present in the handsheets although no tackiness’.

The overall conclusions were that the recyclability of BOTH the Glassine release liner and CCK release liner has been proven without reserve according to the standard EN13430.

PILOT SCALE ASSESSMENT – Since both papers are made of white fibres and in one case with a white coating, a further pilot-scale assessment was carried out to understand the behaviour of these release liners when recycled in a typical mixed recycling process where most of the recycled material will be brown cardboard. The process took a completely recyclable cardboard stream (80%) to which the release papers were added (at 20% by weight). Conditions were chosen to ‘replicate’ the process of a typical recycling plant (the conditions are not identical since the pilot plant trial was a ‘batch’ process compared to a ‘continuous’ process of a typical recycling plant).

PULPING DURATION | 20 MINUTES |

CONSISTENCY | 5% |

PULPING TEMPERATURE | 40°C |

CHEMICAL ADDITIVES | NONE ADDED |

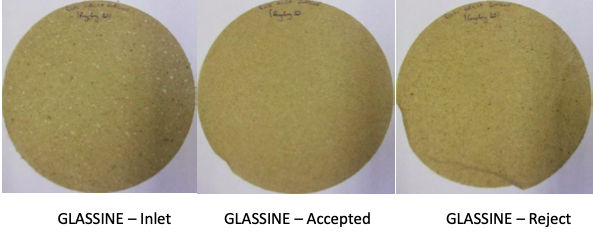

Following pulping a screening step was carried out to simulate 3 to 4 screening stages of a typical recycling plant and handsheets were prepared on different streams (inlet, accepted and rejected pulps) to assess quality of pulp and potential impact of coloured fibres/spots on overall paper quality.

The Glassine recycling trial (mixed 20:80 with brown cardboard), showed large white particles for the ‘inlet pulp’ but after the screening step the final ‘accepted’ pulp was very good.

The CCK recycling trial (mixed 20:80 with brown cardboard), also showed large white particles for the ‘inlet pulp’ but once again after the screening step the final ‘accepted’ pulp was very good.

As part of the screening step, a Somerville classification was carried out on the pulps in cascade to assess the amounts of ‘unwanted materials’ at each stage of screening. The levels were low for both accepted final pulps.

The overall conclusions were that neither type of release liner (Glassine nor CCK) are detrimental to recycling when introduced into mixtures of recyclable papers.

OVERALL CONCLUSIONS – For the assessments made by the Centre Technique du Papier, both Glassine based release liner and CCK based release liner are considered as recyclable according to the EN13430 standard and are also NOT detrimental to recycling when recycled in mixtures with one of the most commonly recycled paper grades (cardboard). In the ‘real world, however, it should be noted that not all repulping operations are as effective at disintegration of paper compared to the ‘standard’ conditions established under the ISO 5263-1 test. This can particularly be the case for some continuous re-pulping operations (drum pulper) where the pulping process conditions may struggle to sufficiently disintegrate the release liner grades. Longer pulping times or higher consistency pulping conditions may be more suitable in these cases.

You can download here the PDF of the full study (also available via our Resources page).